The requirements for motor grease are very high, and it is also very important to choose a high-performance grease

Time:2020-04-24 15:55:00 Browse:20 Editor:Youbao New Material Technology Co., Ltd.

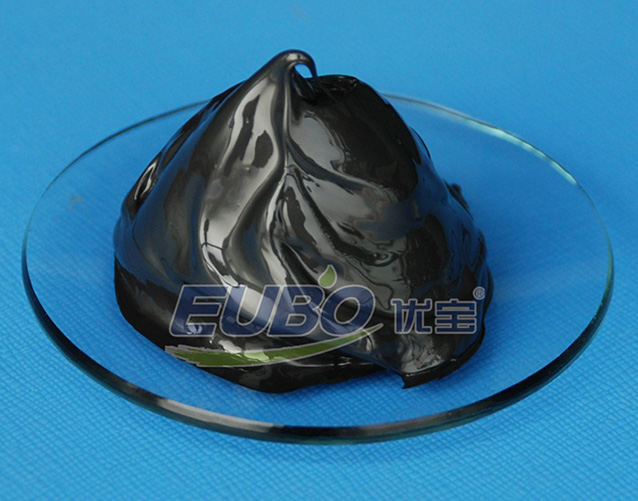

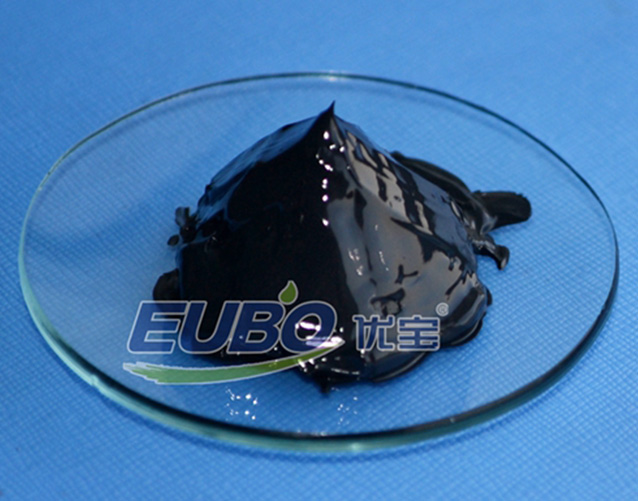

The use of the correct grease for the motor is a very important part of the maintenance of the motor. The harsh environment of the motor has a very high requirement for the motor grease. Therefore, it is very important to choose a high-performance grease. Grease is a semi-solid lubricant composed of base oil, thickener and additives. High-quality motor grease has typical indicators such as viscosity, consistency, oxidation resistance, wear resistance, dropping point, and shear stability. Both performed well.

What are the characteristics of high-quality motor grease?

1、Good adaptability, high and low temperature performance, can be used indoors and outdoors, north and south.

2、It has good lubricity and anti-wear properties, does not shed oil, does not dry up, does not emulsify, does not lose, and the grease itself should not contain solids.

3、Good anti-oxidation performance. After long-term use, the appearance, color, acidity and alkalinity of the grease will change little, without obvious oxidation.

4、It has good fluidity, and generally requires operating temperature between -25°C and 120°C, small starting torque, low operating torque, low power consumption, and low temperature rise.

5、It has strong anti-rust, anti-salt fog ability, good water resistance, and can be used in harsh working environment.

6、Insulation grades are A, E, B grades, and must not contain sulfur and chlorine extreme pressure additives.

7、Long service life can extend the maintenance cycle and reduce bearing consumption.

8、Appropriate consistency and good damping effect can reduce the noise of motor bearings, which is beneficial to environmental protection.

Pay special attention to the following three issues when using grease:

1、Different types of lubricating greases cannot be mixed. When replacing the lubricating grease, the old grease must be cleaned. (Many manufacturers are not very strict on this piece, which will cause the grease to be contaminated and reduce its performance.)

2、Grease should be added once the bearing has been running for 1000~1500h, and the grease should be replaced after 2500~3000h. (There are many motor manufacturers who verify whether the grease meets the requirements of the motor according to these requirements, and have more stringent requirements. This can reflect the performance of the grease to meet the requirements of the motor.)

3、The grease in the bearing should not be added too much or too little, which generally occupies 1/3~1/2 of the empty volume of the bearing chamber; bearings with low speed and light load can be added more; bearings with high speed and heavy load should be added Less. (Different bearings have different requirements for the amount of grease, so customers must add appropriate amounts according to their own conditions when using grease. It can be seen that the more grease is not the better, nor the more expensive the better , But the right one is the best.)

Ubao special lubricating grease research and development, production, sales and service of high-tech enterprises. Launched a series of special lubricating grease, high temperature lubricating grease, damping lubricating grease, thermal conductive silicone grease, gear grease, bearing grease, etc. Widely used in electronic products, household appliances, automobile assembly, office equipment, optical instruments, food and medical equipment, communication digital products, hardware and other industries. Welcome to Ubao to buy.

QQ talk

QQ talk

talk

talk